Note to Sarah: _

<?php

echo("Let's leave this POST and the other PAGE 'as-it-is' for now... i will create another POST for articles and another PAGE for the landing page for the slugs initiative and I will make you the owner of those : ) ");

echo("Basically there is a few different things being 'Demonstrated' on these two pages that we car refer back to if we need to");An article on slugs and the damage they can cause.

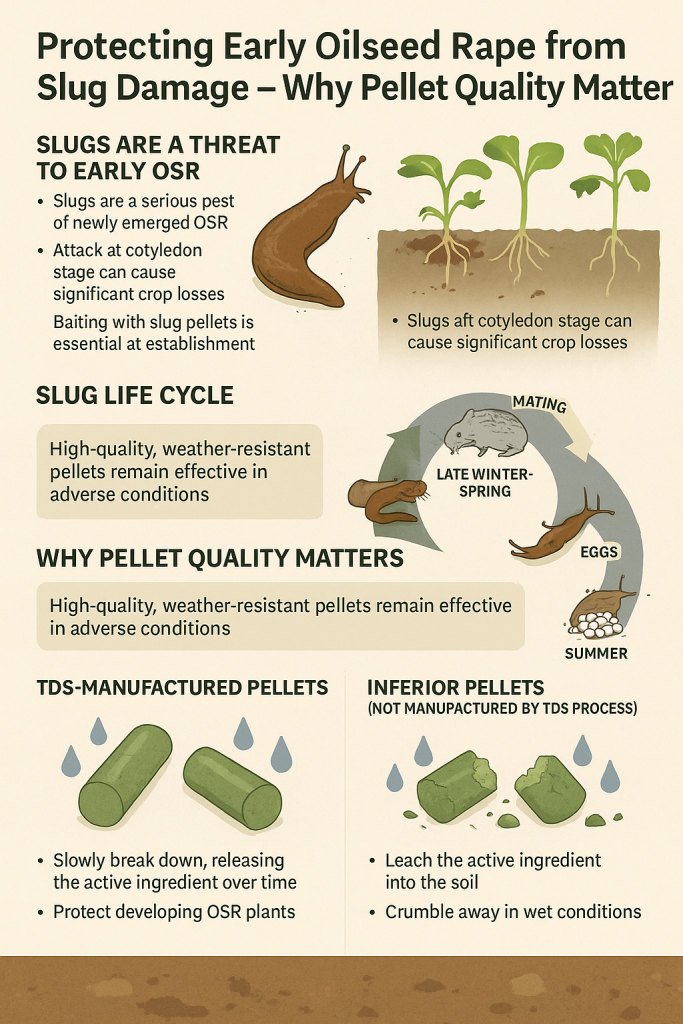

Oilseed rape (OSR) is a valuable break crop, but in the early stages of growth it’s one of the most vulnerable plants on the farm. At the cotyledon stage, just after emergence, the seedlings are delicate and highly susceptible to attack from one of the UK’s most persistent pests: the slug.

Why Slugs Are Such a Threat to Early OSR

Slugs are opportunistic feeders that thrive in moist conditions, making freshly sown OSR fields the perfect hunting ground. They feed on emerging shoots and cotyledons, and even a modest slug population can decimate plant numbers overnight.

Losses at this stage not only affect plant density but also reduce yield potential, leaving crops patchy and uneven right through to harvest.

The Importance of Timely Baiting

The best defence is early intervention. Baiting with slug pellets soon after drilling ensures protection during those critical first weeks. However, not all pellets are created equal — and choosing the wrong product can leave gaps in your control strategy.

Why Pellet Quality Makes All the Difference

Premium slug pellets manufactured using the TDS (Total Disintegration System) process are designed for maximum weather resistance. Rain, dew, and fluctuating temperatures won’t immediately compromise their structure. Instead, they break down slowly and evenly, ensuring the active ingredient is released in a controlled way over time. This means slugs encounter a lethal dose whenever they feed — even in challenging weather.

Why Savvy Growers Prefer TDS Pellets

By contrast, cheaper pellets that aren’t made using the TDS process tend to:

- Crumble or fragment after just a short exposure to rain or damp conditions.

- Leach the active ingredient into the soil far more quickly, reducing their effectiveness.

- Leave the crop unprotected at its most vulnerable stage — especially those tender cotyledons that slugs target first.

Protecting Your Investment

OSR establishment is expensive, and every lost plant is a dent in your potential return. Investing in high-quality slug pellets might seem like a small decision, but in reality, it’s a cornerstone of crop protection. The extra durability and consistent release of the active ingredient mean better protection, fewer gaps in coverage, and greater peace of mind that your crop will make it through the risky early phase.

Key Takeaway:

Don’t let inferior pellets put your OSR at risk. Use weather-resistant, TDS-manufactured slug pellets from the start to keep slugs at bay and give your crop the best possible chance to establish strong, uniform stands.

Farmy McFarmerson

I thought this infographic might be helpful. But it wasn’t.

Rob Suckling ~ De Sangosse

Download the Infographic on the button below. Don’t listen to Rob … his standards are unrealistic. Its very helpful and shows you what a broken pellet looks like in case you didn’t know. Click the button below and grab your copy before they’re all gone.

Check Out Our Ultimate Guide to Say ‘Adios Molloscachachoes’ to Slimy Pests…

… And Be Rid of Slugs in Your Field…

Why Pellet Quality Makes All the Difference

Premium slug pellets manufactured using the TDS (Total Disintegration System) process are designed for maximum weather resistance. Rain, dew, and fluctuating temperatures won’t immediately compromise their structure. Instead, they break down slowly and evenly, ensuring the active ingredient is released in a controlled way over time. This means slugs encounter a lethal dose whenever they feed — even in challenging weather.